USŁUGI

Nasze najważniejsze działy

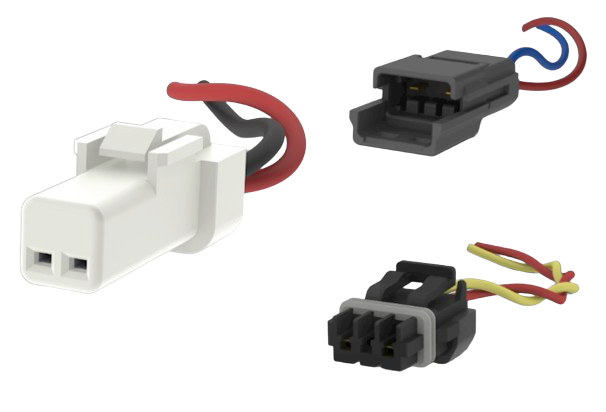

Połączenia przewodów

Nasze rozwiązania połączeniowe w segmencie wiązek elektrycznych są niezwykle innowacyjne i stanowią przełomowe podejście do tego tematu.

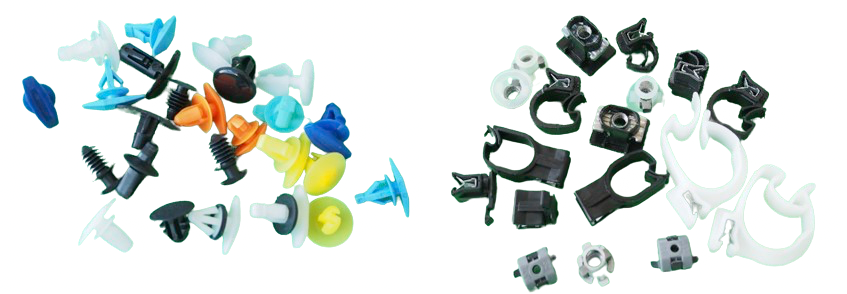

Fasteners

Detale z działu fasteners stanowią fundament naszej firmy i są jednymi z najdłużej działających projektów.

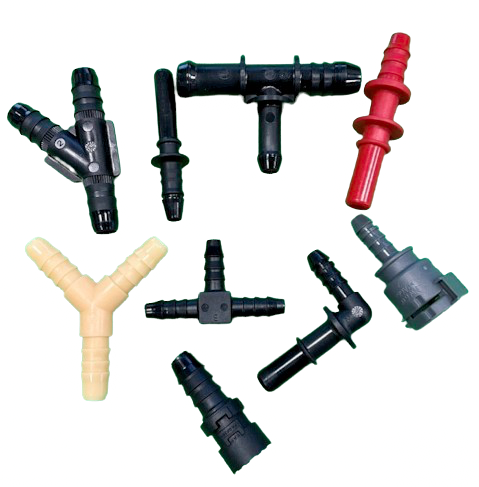

Komponenty

Wraz z rozwojem naszej firmy, poszerzyliśmy nasze usługi o wtryskarki większych rozmiarów, co umożliwiło nam rozpoczęcie produkcji większych detali.

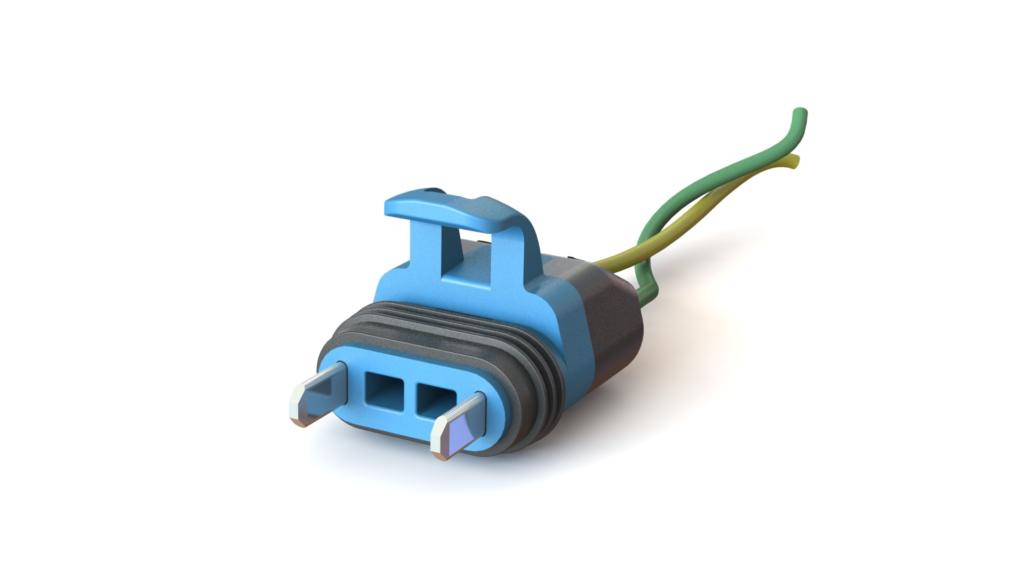

Połączenia przewodów

Nasze rozwiązania połączeniowe w segmencie wiązek elektrycznych są niezwykle innowacyjne i stanowią przełomowe podejście do tego tematu. Wykorzystanie nowoczesnej technologii i kreatywnego podejścia pozwoliło nam rozwiązać wiele problemów, z którymi nasi klienci wcześniej się borykali, takich jak szczelność czy łatwość zastosowania w różnych branżach. Dzięki wprowadzeniu nowoczesnych technologii, jesteśmy w stanie zapewnić nie tylko doskonałą jakość połączeń, ale również skuteczność w radzeniu sobie z wyzwaniem szczelności. Nasze rozwiązania są starannie zaprojektowane i testowane, aby spełniać najwyższe standardy branżowe i sprostać oczekiwaniom naszych klientów. Nasze innowacyjne podejście do tematu wiązek elektrycznych pozwala nam w pełni zrozumieć potrzeby naszych klientów i dostarczyć im produkty, które w 100% spełniają ich oczekiwania. Dążymy do ich ciągłego doskonalenia, aby zapewniały przewagę konkurencyjną i oczekiwany poziom jakości.

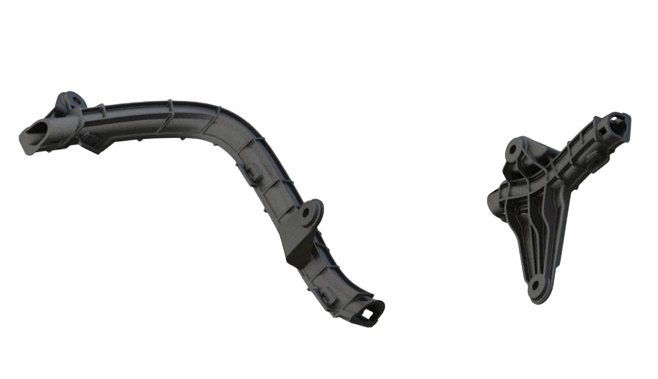

Fasteners

Detale z działu fasteners stanowią fundament naszej firmy i są jednymi z najdłużej działających projektów. Od samego początku skupiliśmy się na ich produkcji, a przez lata zdobyliśmy ogromne doświadczenie, które przyczyniło się do wypracowania stabilnego procesu produkcyjnego oraz zapewnienia satysfakcji klientom z naszych usług. Nasza zdolność do wytwarzania wysokiej jakości detali z działu fasteners opiera się na bogatym dziedzictwie i wiedzy, którą zgromadziliśmy na przestrzeni lat. Posiadamy zespół wykwalifikowanych specjalistów, którzy doskonale znają tajniki produkcji, jak również stale podnoszą swoje umiejętności, aby sprostać dynamicznym wymaganiom rynku. Jesteśmy w stanie dostarczać klientom nie tylko wysokiej jakości produkty, ale także kompleksowe rozwiązania dopasowane do ich indywidualnych potrzeb. Nasze detale są starannie projektowane, testowane i produkowane z najwyższą dbałością o szczegóły, co gwarantuje ich niezawodność i trwałość.

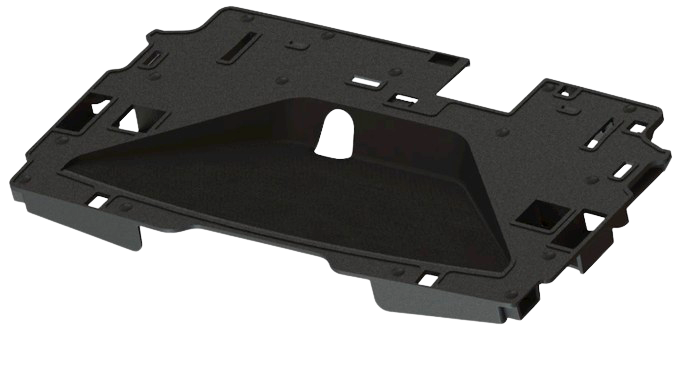

Komponenty

Wraz z rozwojem naszej firmy, poszerzyliśmy nasze usługi o wtryskarki większych rozmiarów, co umożliwiło nam rozpoczęcie produkcji większych detali. Dzięki temu, jesteśmy w stanie kompleksowo podejść do wymagań klienta, a komponenty o większych gabarytach nie stanowią dla nas problemu.

Inwestycja we wtryskarki większych rozmiarów była naturalnym krokiem w rozwoju naszej firmy, pozwalając nam na elastyczność i zdolność do realizacji różnorodnych projektów. Nasza zdolność do produkcji większych detali pozwala nam sprostać nawet najbardziej wymagającym potrzebom klientów.